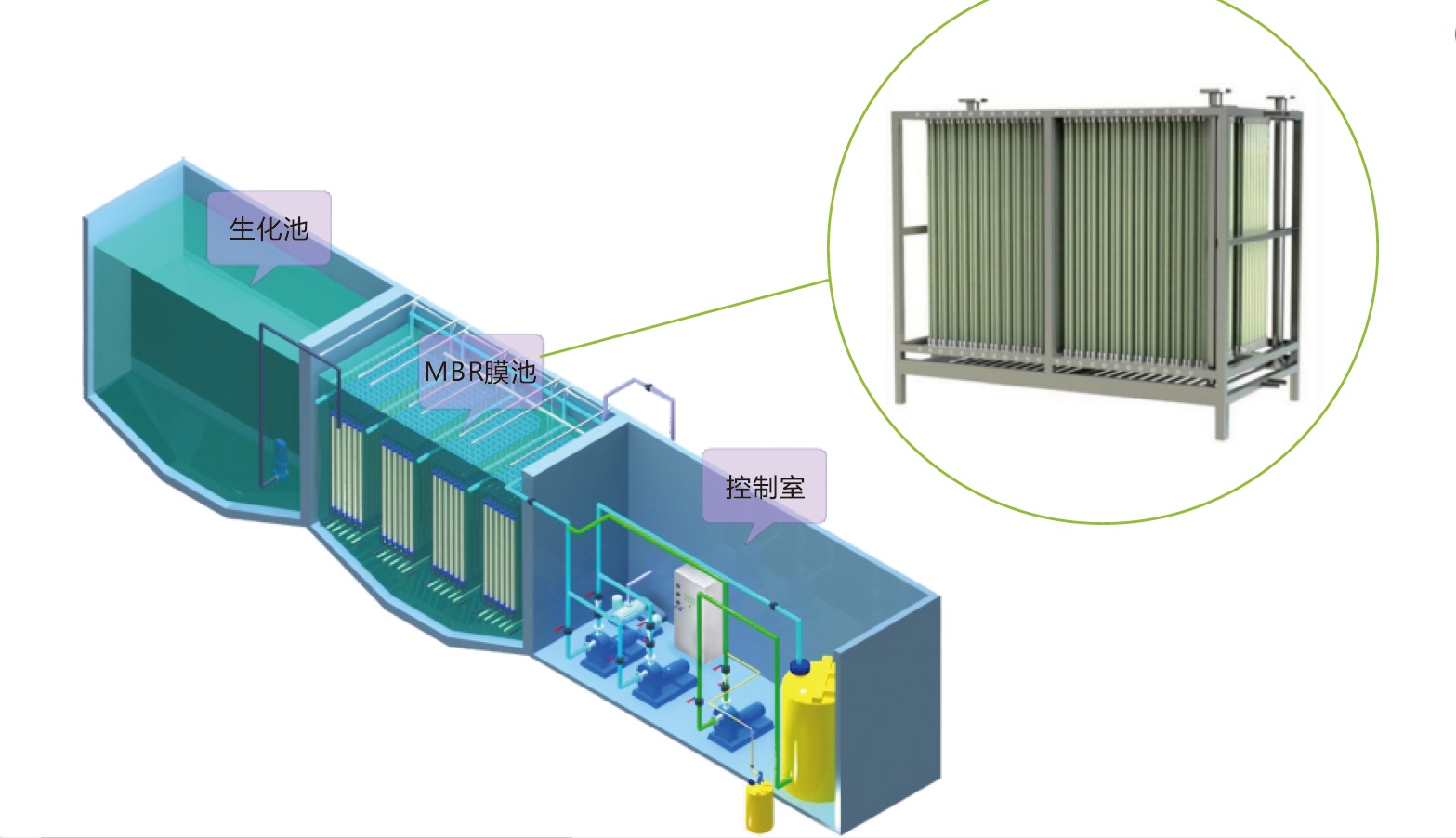

Engineering Product - Membrane Bioreactor (MBR)

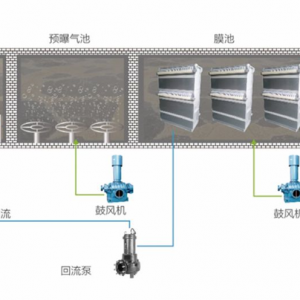

Membrane Bioreactor (MBR) is a novel sewage treatment technology that integrates hollow fiber membrane modules to separate and filter sludge-containing wastewater in the biochemical reaction tank, combining membrane separation technology with the activated sludge process.MBR.

Characteristics of Membrane Bioreactor (MBR) Technology

1、High pollutant removal efficiency, good effluent quality, and directly reusable.

The high filtration precision of the membrane separation component (MBR membrane) ensures clear and transparent effluent, fully meeting reuse water standards.

2、Hydraulic retention time (HRT) and sludge retention time (SRT) are completely separated.

Due to the MBR completely retaining activated sludge in the biochemical reaction tank, it achieves full separation of hydraulic retention time (HRT) and sludge retention time (SRT), making system operation control more flexible and stable.

3、Long sludge age and low residual sludge production.

Due to the long sludge age, microorganisms in the biochemical reaction tank are predominantly in the endogenous decay phase, and the membrane bioreactor (MBR) also functions as a "sludge digestion tank," thereby significantly reducing residual sludge production and greatly lowering residual sludge treatment costs.

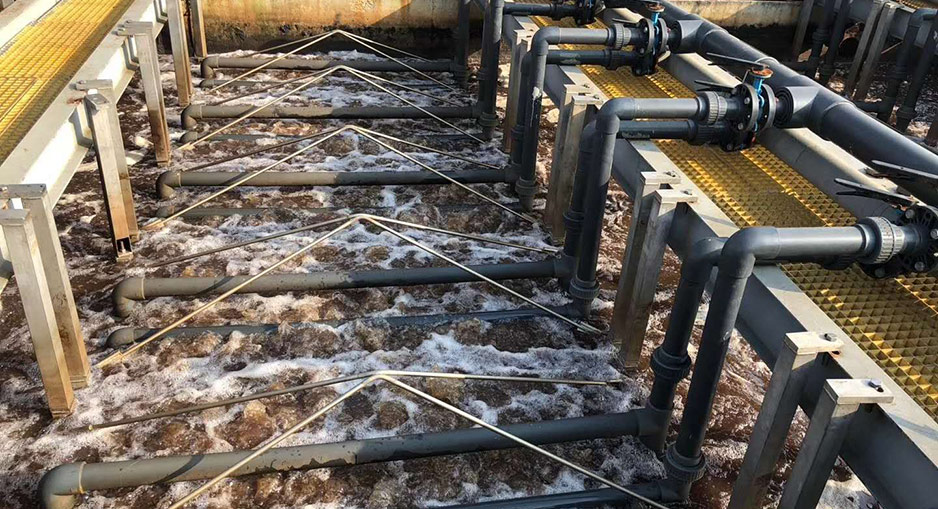

4、High biomass concentration, high volumetric load, and reduced footprint.

The MBR completely retains the activated sludge within the biochemical reaction tank, achieving a sludge concentration of approximately 7000-12000 mg/l. The biomass concentration in the biochemical reaction tank reaches 2-3 times that of conventional activated sludge processes, resulting in high volumetric load and reduced footprint.

5、Effective nitrogen removal.

The MBR utilizes membrane separation modules (MBR membranes) to completely retain the activated sludge within the biochemical reaction tank, thereby facilitating the retention, growth, and proliferation of slow-growing nitrifying bacteria and significantly enhancing the system's nitrogen removal efficiency

.

6、Strong resistance to load shocks.

The MBR completely retains activated sludge in the biochemical reaction tank. During system operation, the activated sludge varies with changes in the influent organic matter concentration, reaching a dynamic equilibrium, which greatly enhances the system's resistance to load shocks and ensures stable effluent water quality.

7、Easy automatic control and convenient operation management.

Easy to achieve fully automatic control, simple management and operation, enabling unmanned operation.

Application area

Refractory industrial wastewater: chemical industry wastewater, printing and dyeing wastewater, pharmaceutical wastewater, coking wastewater, landfill leachate.

High-concentration organic wastewater: food processing wastewater, aquaculture wastewater, etc.

General wastewater: domestic wastewater, urban sewage, etc

Upgrading and renovating sewage treatment facilities, etc

苏公网安备 32050902101529号

苏公网安备 32050902101529号 Scan WeChat QR to Follow

Scan WeChat QR to Follow