Sulco Environmental Protection independently researches and develops standardized MBR membrane modules and integrated sewage treatment equipment, renowned as well-known brands both domestically and internationally. The company can also provide matching reclaimed water reuse equipment according to client requirements, produce various sewage treatment devices, and offer products with treatment capacities ranging from 1-500 m³/h tailored to specific client conditions. These systems effectively remove pollutants such as COD, BOD, and suspended solids. Inquiries are welcome via phone!MBR.

MBRIntegrated sewage treatmentApplication areas:

The MBR membrane module integrated sewage treatment equipment produced by our company is a high-tech product that organically combines biotechnology and membrane technology. It features modular design, intelligence, easy transportation, quick installation, high efficiency, energy-saving capabilities, and requires no dedicated supervision. It is suitable for decentralized domestic sewage treatment and similar industrial organic wastewater treatment on small to medium scales, including rural domestic sewage, public toilets, independent villas, tourist attractions, hotel domestic sewage, tourist resort sewage, highway service area sewage, river interception projects, and emergency wastewater treatment. Currently widely applied across China, it is an ideal solution for decentralized domestic sewage treatment.

The advantages of MBR integrated sewage treatment equipment

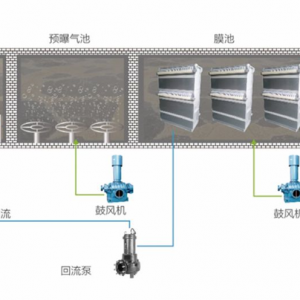

1、Produces High-quality Water

The process adopts an anoxic-aerobic MBR technology, integrating membrane modules with the bioreactor tank into a single-unit device. This represents a comprehensive upgrade to conventional MBR technology, offering advantages of high efficiency and low energy consumption compared to traditional methods. It has successfully established an anoxic-aerobic environment, achieved near-zero discharge of organic sludge, accomplished gasification dephosphorization of wastewater and synchronous nitrogen removal from sludge. The effluent quality remains stable over the long term, meeting the stringent Class 1A standard (China's national discharge standard).

2、Small Floor Area

The highly integrated MBR membrane offers advantages of high flux and reduced number of membrane modules, enabling a large treatment capacity with a smaller footprint.

3、Save Operating Costs

Highly integrated design with low power consumption, saving on electricity costs; employs PVDF hollow fiber membranes that eliminate the need for backwashing or external cleaning, extended chemical cleaning cycles reduce chemical usage and associated costs; unmanned operation capability minimizes labor expenses.

4、High Degree Of Automation

Highly integrated, significantly simplifying processes; the equipment’s electrical control system utilizes PLC-based fully automatic control, enabling highly intelligent operation with automatic water production and cleaning. Noise levels remain below Class II area standards, requiring no dedicated personnel, and enabling online and remote control.

5、Long Service Life

The blower, water pump, and electrical components in the control cabinet utilize international imported or domestic renowned brands, ensuring reliable performance and extended service life. The equipment tank is constructed with carbon steel coated with FRP (Fiberglass Reinforced Plastic) for anti-corrosion, offering high mechanical strength and a service life of up to twenty years.

6、Quick Installation And Use

No civil construction required; upon delivery, the equipment only needs connection to water and electricity supplies, followed by simple commissioning for immediate operation. Compact footprint, minimal infrastructure work, short project cycle, and low investment costs.

MBR Integrated Sewage Treatment Equipment Configurations for Villages and Towns: ♦ Anoxic Tank: Carbon Steel with Anti-corrosion Coating ♦ Aerobic Tank: Carbon Steel with Anti-corrosion Coating ♦ MBR Membrane Tank: Integrated (within the Aerobic Tank) ♦ Membrane Modules: Polyvinylidene Fluoride (PVDF) Hollow Fiber MBR Membrane Modules ♦ MBR Membrane Online Cleaning System ♦ Clean Water Tank: Carbon Steel with Anti-corrosion Coating ♦ Equipment Room: Carbon Steel with Anti-corrosion Coating ♦ Electrical Control System: PLC Control (Intelligent Automation System)

Sulco Integrated Sewage Treatment Equipment adopts polyvinylidene fluoride (PVDF) MBR membranes, with effluent quality meeting national discharge standards. Classification of integrated terminal sewage treatment facilities: Material: Carbon steel/FRP (Fiberglass Reinforced Plastic)/Stainless steel; Shape: Rectangular/Cylindrical; Installation method: Above-ground/Underground/Semi-underground.

苏公网安备 32050902101529号

苏公网安备 32050902101529号 Scan WeChat QR to Follow

Scan WeChat QR to Follow