The HCOS system is a groundbreaking advanced oxidation device. Its working principle involves utilizing hydroxyl radicals (·OH) generated on the catalyst surface by ozone to oxidize trace, non-biodegradable organic substances in water. This achieves deep COD removal and water purification, maintaining effluent COD below 30 mg/L1, reliably meeting national discharge (local Class IV) or reuse water quality requirements. It is a complete oxidation technology with no selectivity

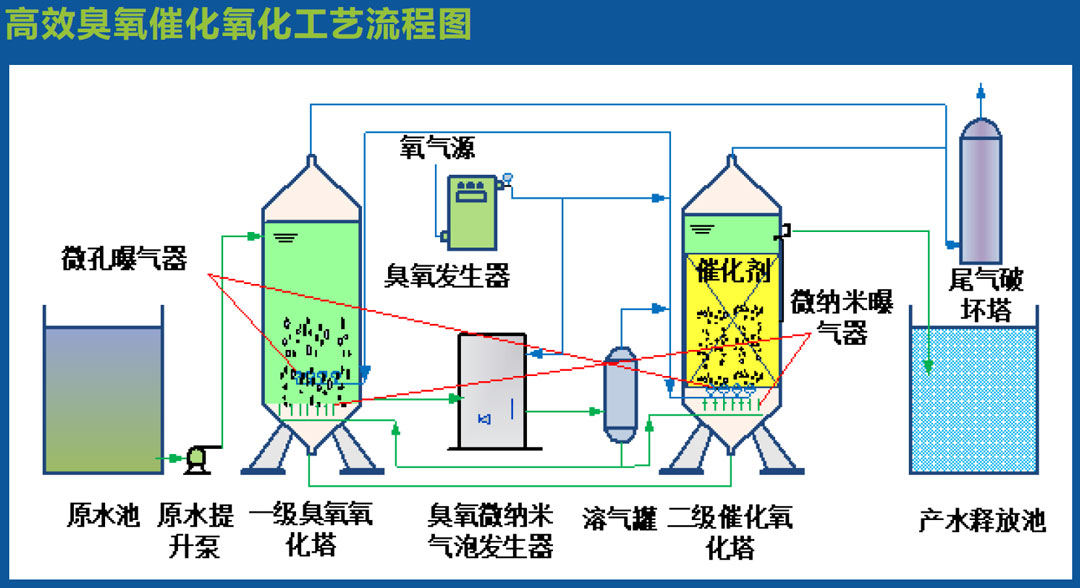

Ozone is globally recognized as the most environmentally friendly strong oxidizer. The catalytic ozonation process, which uses ozone (O₃) gas as the oxidizer and harnesses hydroxyl radicals (·OH) generated on the surface of specialized catalysts to oxidize and remove organic substances from water, represents a primary pathway in advanced oxidation technology (AOT). Hydroxyl radicals (·OH) exhibit an oxidation-reduction potential of 2.85 V, second only to fluorine (3.06 V), granting them exceptionally strong oxidative capacity. When reacting with organic compounds, hydroxyl radicals (·OH) indiscriminately, thoroughly, and rapidly decompose refractory organic pollutants in water. The organic radicals generated during these reactions further participate in chain reactions with ·OH, accelerating the oxidation process and ultimately mineralizing organic matter into harmless substances such as water and carbon dioxide. Our company has innovatively developed a novel high-efficiency catalytic ozonation process (High-efficiency Catalytic Ozonation System, HCOS), one of the most advanced catalytic oxidation technologies in China. HCOS integrates ozone micro-nano pressurized aeration technology, ozone hydroxylation technology, and ozone high-efficiency catalytic reaction technology, marking a groundbreaking innovation in the field of advanced oxidation technologies.

Characteristics of HCOS Technology

★ The High-Efficiency Catalytic Ozonation Process (HCOS) uses ozone as the primary oxidizer. Based on the nature of organic pollutants in wastewater, selective catalysts are loaded to achieve an organic integration of multiple advanced oxidation technologies within a single system. Different oxidation mechanisms synergize and complement each other, enhancing reactor performance, efficiency, and operational stability. The COD removal ratio of O₃ ranges between 1:0.4–1:2 (depending on the type, properties, and concentration of organic matter in the water).

★By integrating ozone pressurization technology, HCOS enables the coordinated operation of microporous aeration and micro-nano aeration in either atmospheric or pressurized reactors. This significantly improves ozone reaction rates and utilization efficiency (ozone utilization can exceed 95%), reduces ozone dosage, minimizes the number and volume of reaction towers, and lowers system construction and operational costs. HCOS exhibits strong adaptability, applicable to over 95% of organic wastewater types, with distinct advantages in treating high-biotoxicity, high-TDS, and highly refractory wastewater. It adapts well to fluctuations in influent quality and quantity, ensuring stable compliance with discharge standards even under suboptimal design conditions. HCOS requires only pH control during operation and produces no secondary pollution.

★ Implementing simple pretreatment processes (e.g., removal of suspended solids, colloids, silica, and hardness) prior to HCOS effectively prevents catalyst contamination and poisoning. The catalyst’s crystalline structure remains stable under alkaline conditions, ensuring long-term, efficient, and stable operation of the ozonation system.

★ Combining HCOS with biological processes reduces overall project investment and operational costs. HCOS can serve as a pretreatment to lower wastewater biotoxicity and enhance biodegradability (B/C ≥ 0.3) or as a post-treatment to improve effluent quality (typically meeting Class IV surface water standards).

★ HCOS is highly suitable for zero-liquid-discharge (ZLD) projects involving high-salinity brine. Under conditions with chloride ion concentration < 20,000 mg/L, TDS < 80,000 mg/L, and COD < 800 mg/L, organic removal rates remain stable at 60%–80%. The final effluent achieves a colority < 10-fold and COD < 150 mg/L. At this quality, subsequent evaporation-crystallization produces monovalent and divalent salts meeting industrial-grade TOC standards for dry salts.

★ HCOS is a mature technology validated through long-term operation in multiple practical projects. It is primarily applied in treating high-salinity, high-biotoxicity, and highly refractory wastewater, with cost-effective investment and operational expenses. The system adapts to hourly treatment capacities ranging from tens to thousands of cubic meters.

苏公网安备 32050902101529号

苏公网安备 32050902101529号 Scan WeChat QR to Follow

Scan WeChat QR to Follow