EDIequipment typically uses reverse osmosis (RO) purified water as its feed water. The conductivity of RO purified water generally ranges from 40 to 2 μS/cm (25°C). The resistivity of EDI-purified water can reach up to 15 MΩ·cm (25°C). However, depending on the application of the deionized water and the system’s processes and configuration, EDI-purified water is suitable for producing ultrapure water with resistivity requirements ranging from 1 to 18.2 MΩ·cm (25°C).

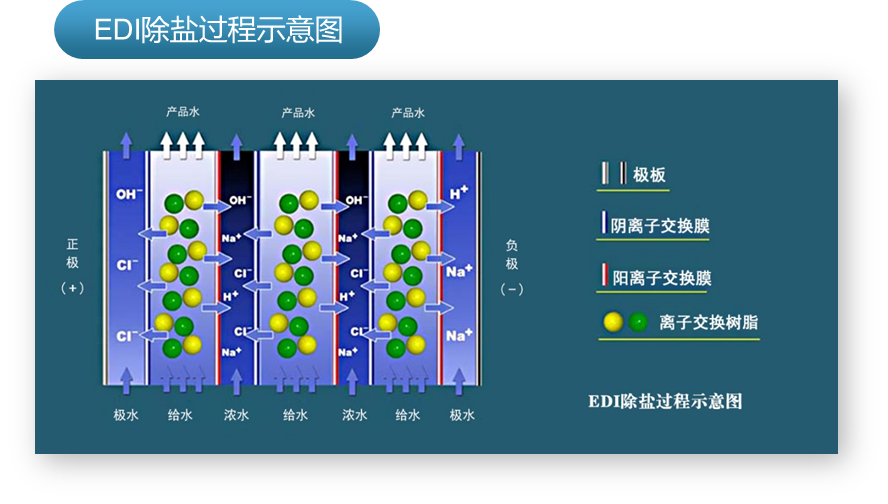

EDIElectrodeionization deviceis formed by sandwiching ion exchange resin between anion/cation exchange membranes. The working principle of EDI is illustrated in the diagram. Within the EDI module, a certain number of EDI units are separated by mesh spacers to form concentrated water chambers. Anode and cathode electrodes are installed at both ends of the unit group. Driven by direct current, anions and cations in the feed water passing through the freshwater chamber migrate through the respective anion/cation exchange membranes into the concentrated water chambers, thereby being removed from the freshwater stream. The water flowing through the concentrated water chambers carries the ions out of the system, forming concentrated wastewater.

Traditional ultrapure water systems include electrodialysis and ion exchangers (cation exchange beds, anion exchange beds, mixed-bed exchangers). Our newly developed ultrapure water equipment utilizes EDI (Electrodeionization) technology, which effectively removes nearly all cations and anions from water. The effluent resistivity can stably exceed 15 MΩ·cm, with advantages such as continuous operation, chemical-free operation, high water utilization efficiency, and significant potential in ultrapure water production processes.

Therefore, EDI + reverse osmosis systems are suitable for: Industrial high-purity water Medical ultrapure water Electronic reverse osmosis pure water systems Ultrapure water systems for the electronics industry

苏公网安备 32050902101529号

苏公网安备 32050902101529号 Scan WeChat QR to Follow

Scan WeChat QR to Follow