Integrated Water-Fertilizer Technology (Fertigation)

Integrated water-fertilizer technology, also known as fertigation, is a modern agricultural technique that combines drip irrigation with fertilization. This method utilizes a drip irrigation system to deliver water and fertilizers simultaneously, integrating their management and application. By using water as a carrier, nutrients are supplied to crops in an optimized combination within the soil, ensuring efficient absorption.

The system is designed based on the crop’s full growth cycle requirements, providing precise amounts of water and nutrients at the right time, in appropriate proportions, and tailored to different growth stages. This achieves high precision in irrigation volume, timing, fertilizer dosage, and application schedules. Key features include synchronized water-fertilizer delivery, centralized supply, and long-term benefits from a single implementation, significantly improving water and fertilizer utilization efficiency.

This technology is suitable for facility-based agriculture (e.g., greenhouses, solar greenhouses for vegetable cultivation) and economically valuable crops such as field crops and fruit trees.

Intelligent Integrated Water-Fertilizer System

The intelligent integrated water-fertilizer system requires no manual control. It automatically detects when irrigation or fertilization is needed and can activate or deactivate irrigation zones autonomously. The system operates on fixed monthly, weekly, or daily schedules, cycling based on preset daily irrigation durations and interval periods. It can automatically start or stop irrigation based on soil moisture parameters and program fertilization by time, ratio, water volume, or EC/pH values.

Background of Smart Agriculture

When it comes to drip irrigation technology, nearly every grower thinks of Israel. By leveraging the water-saving advantages of drip irrigation, Israel addressed its water scarcity challenges, transforming deserts into a "land of fruits and vegetables." The success of Israel’s drip irrigation technology has inspired its adoption in many countries and regions. However, as technology continues to advance, drip irrigation systems will also require updates and iterations.

As a major agricultural nation, China is also a significant water consumer. However, the country faces severe water shortages, and water resource crises have become a critical constraint on sustainable economic development. Agricultural water usage in China is highly inefficient, with low irrigation water utilization rates. Pursuing a path of technology-driven water-saving agriculture to achieve rational water resource use will not only conserve water but, more importantly, enhance agricultural water efficiency, reduce labor costs, and improve ecological environments. This is key to achieving sustainable and modernized agriculture in China.

Agricultural water use in China accounts for approximately 80% of total water consumption. Due to generally low agricultural irrigation efficiency, water utilization rates are only around 45%, whereas regions with high water use efficiency achieve 70%–80%. Therefore, addressing agricultural irrigation water use and alleviating water scarcity are critical. Our smart agricultural irrigation system emerged in this context.

The smart agricultural irrigation and fertilization system operates without manual control. It automatically detects when irrigation is needed and determines the duration. The system can autonomously activate irrigation zones, shut them off, and execute cycles based on fixed monthly, weekly, or daily schedules. It operates according to preset daily cycle durations and interval periods, and can automatically start or stop irrigation based on soil moisture parameters. Fertilization can be programmed to align with irrigation schedules, where injection quantities are determined by time, predefined ratios, water volume, or tailored to EC/PH values.

(1) Water and Fertilizer Savings

— Proportional regulation ensures optimized utilization of water and fertilizer.

(2) Yield Increase

— Deployment of the system can boost production by 30-50%.

(3) Time and Labor Savings

— Reduces human labor cost input and management.

(4) Intelligent Control

— Automatically controls irrigation via feedback based on parameters such as soil moisture and temperature.

(5) Scientific Research

— The system is highly scalable.

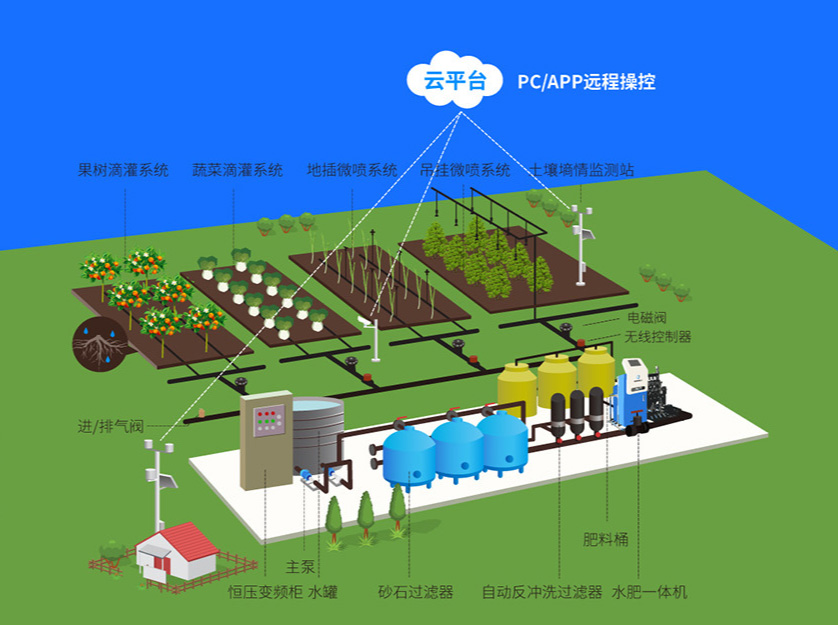

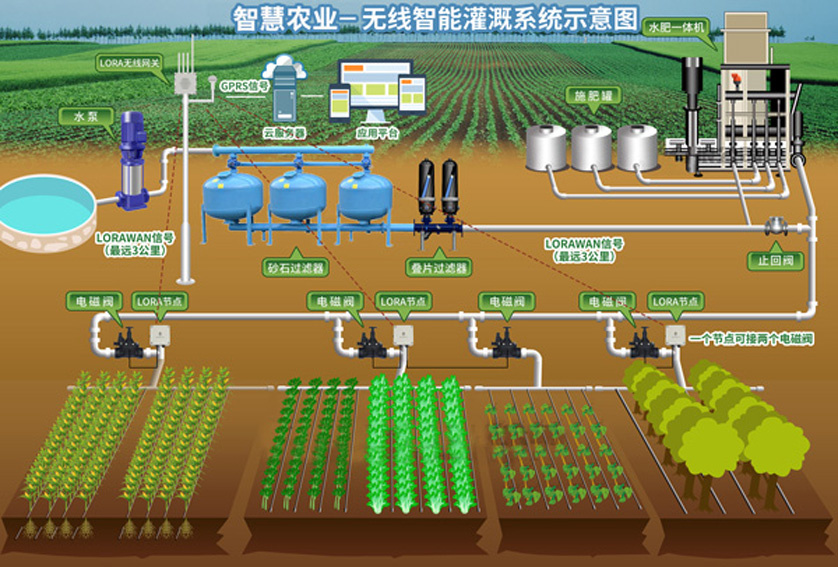

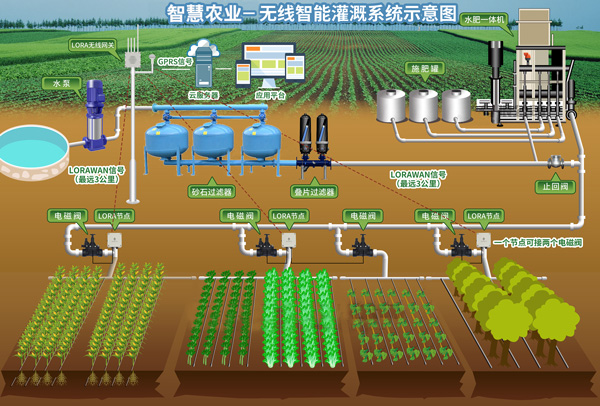

The Smart Water-Fertilizer Integrated Drip Irrigation System is an advanced agricultural production facility that integrates cutting-edge technologies such as the Internet of Things (IoT), mobile internet, and automatic control. Relying on soil sensors and wireless communication networks, the system enables automatic sensing, alerting, analysis, and control of soil moisture levels. By controlling irrigation equipment such as solenoid valves and water pumps, it automatically adjusts soil moisture for crops, significantly reduces reliance on manual labor, operates economically and energy-efficiently, and achieves unmanned automated irrigation management.

Construction of a Smart Water-Fertilizer Integrated Drip Irrigation System

The Smart Water-Fertilizer Integrated Irrigation System enables automated management of water and fertilizer for agricultural producers. The system consists of an upper computer software system, regional control cabinets, branch controllers, transmitters, and data acquisition terminals, which integrate with water supply systems to achieve automated control26. It monitors and regulates irrigation duration, fertilizer concentration, and water supply volume during irrigation operations27. Transmitters (including soil moisture transmitters and flow transmitters) continuously monitor irrigation status. When soil humidity in the irrigation zone reaches a preset lower threshold, solenoid valves automatically open, and close once soil moisture or liquid level meets predefined irrigation quotas68. The system schedules rotational operation of solenoid valves across the entire irrigation zone based on time intervals, while allowing manual control of irrigation and soil moisture data collection68. Coordinated operation of all components enhances irrigation water efficiency by 20-60%, reduces energy consumption, lowers labor intensity, and decreases operational costs

Water-Fertilizer Integration Technology is an innovative agricultural method that combines irrigation and fertilization. Based on the fertilizer requirements of crops during different growth stages and soil characteristics, it automatically detects, mixes, and supplies water and fertilizers with precision, enhancing water and fertilizer utilization. The system components include: main water pump, constant-pressure frequency conversion control cabinet, filters, fertilization unit (water-fertilizer integrated machine), protection and metering devices (flow meters, pressure sensors, EC, pH, valve series, etc.), water supply pipeline network system, wireless/wired valve control system, and field irrigation emitter system.

Irrigation Design

Types of Smart Drip Irrigation Systems: Based on water supply methods, smart drip irrigation systems include constant-flow emitters (self-compensating) and adjustable micro-emitters. The selection of drip tubing must align with each plant's water requirements, soil characteristics, and the scale of the smart drip irrigation system

Constant-flow emitters: They are non-adjustable and always deliver the same amount of water. Ideal for plants requiring consistent water quantities, typically mature or established specimens. This type of drip irrigation is the simplest and most economical.

Self-compensating emitters: These are constant-flow (non-adjustable) drip heads that compensate for pressure differences to ensure consistent water delivery. They are recommended for use when the length of drip tubing exceeds 25 meters or when there are significant pressure variations.

Adjustable emitters: This type of emitter allows the flow rate to be adjusted up to 60 liters per hour. They are specifically designed for plants in active growth or areas with significant temperature or humidity fluctuations.

Micro-sprinklers: This irrigation method mimics microrain. These miniature sprinklers project extremely fine water droplets (even functioning as misters) across a radius of up to 5 meters. When using this system, pay attention to the irrigation schedule to avoid leaf burn from sunlight exposure.

Conventional polyethylene pipes are standard tubing compatible with drip emitters. Compared to other pipe types (e.g., porous pipes or integrated-emitter tubing), their key advantage lies in precise emitter placement for optimized water distribution and targeted irrigation46. Users can combine adjustable emitters, self-compensating emitters, or even micro-diffusers based on specific plant water requirements12. Diameter selection depends on: Number of irrigation points Coverage area Terrain characteristics14 The 4 mm diameter tubing is ideal for: Small-scale drip systems (e.g., up to 12 pots or 15 linear meters) Branching from larger mainlines45

Booster pump parameter design:Pump flow rate data = Main pipe flow capacity (i.e., economic water conveyance capacity of the main pipe) + Planned irrigation area. The pump flow rate can be selected as 25 m³/h. The finalized pump parameters are: Flow rate: 25 m³/h Head: 32 meters Power: 4 kW.

Pump control methods

Design a single pump operating in a 1-drag-1 configuration, with a pressure sensing device installed on the main pipeline. When the field valve opens, the pump activates. The variable frequency pump control cabinet system adjusts the output frequency through the built-in PID regulator in the frequency converter, based on the measured pipeline pressure, to achieve constant pressure water supply in the network. The frequency converter’s over-limit signal (typically used as the network pressure signal) can notify the PLC to switch the variable frequency pump when appropriate. To prevent water hammer phenomenon, the pump’s start/stop will be interlocked with its outlet valve.

Sand and gravel filter selection

Since the water source is surface water, containing impurities primarily composed of organic matter, selecting a "fully automatic (120-mesh) filter" based on the water quality requirements of the chosen emitters will sufficiently meet the demands of this drip irrigation system.

Design two vessels, each with a diameter of 600 mm and a flow rate of 40 m³/h; two carbon steel sand filters, flange-type, installed horizontally;

Sand media filters are primarily used to treat organic impurities and algae in water, mainly suitable for primary filtration of open water sources such as reservoirs, ponds, and canal water. They are typically paired with disc filters as secondary filtration in subsequent stages.

1. Set up a fixed-time cleaning program.

2. Filter Inlet/Outlet Differential Pressure Sensing Cleaning Procedure;

Disc Filter Selection

Design a 2-inch single-unit filter body with three groups in parallel; flow rate: 20 m³/h per group, total flow rate of 60 m³/h, adopting fully automatic cleaning control. When a certain differential pressure is reached or within a set time, the system automatically initiates the backwash process. The controller adjusts the valve to reverse the water flow direction, closing the main channel via the unidirectional diaphragm at the filter bottom. Backwash water enters six sets of nozzle channels, increasing water pressure in the piston chambers connected to the nozzles. The piston moves upward, overcoming the spring pressure on the disc stack, and releases space at the top of the disc stack. Simultaneously, backwash water is sprayed at high speed through 35×6 nozzles above the six nozzle channels along the tangential direction of the discs, causing the discs to rotate and separate uniformly. The spray flushes impurities trapped on the disc surfaces. When backwash concludes, the water flow reverses again, the discs are recompressed, and the system resumes filtration. The backwash controller operates simply, enabling comprehensive control of the filter or workstation via differential pressure, time, or a combination. The disc filter element requires no replacement, with a service life of up to 15 years. Cleaning control method:

1. Set up a fixed-time cleaning program.

2. Filter Inlet/Outlet Differential Pressure Sensing Cleaning Procedure;

Smart Water-Fertilizer Integrated Machine

The structure of the water-fertilizer integrated machine system includes: control cabinet, touchscreen control system, fertilizer mixing hardware system, and wireless data acquisition and control system. It supports real-time data monitoring and control of front-end devices via PC and WeChat platforms.

·Time control: Set time irrigation

·Fertilizer-water ratio: Set flow ratio to control the fertilizer-water ratio

·External signal control: Soil moisture controls the pump switch.

·Wireless control: Wirelessly collect sensor values and control

System features

·Fertilizer control: Control by percentage of fertilizer supply

·Flow control: Determine valve status based on flow sensor values in each greenhouse.

·Selectable fertilization or direct irrigation

·Irrigation utilizes the pressure of the existing irrigation network and does not require a pressure pump.

·Alarm and stop: Trigger an alarm and stop operation when the pressure exceeds the upper limit.

·报警及停止:超出土湿上限值时发出报警及停止运行

·One-click irrigation: Emergency irrigation (Manual irrigation)

·Temporary stop: One-click operation stop

·Valve data collection in irrigation areas using wireless transmission to save cabling costs

hardware feature

·Includes embedded field lower-level controllers, signal acquisition modules, equipment drive modules, and a human-machine interaction 7-inch touch screen, capable of achieving precise irrigation control, water-fertilizer information acquisition, and cloud server interaction.

The Smart Water-Fertilizer Machine features fast computing capability, combined with the latest sensing technology and big data analysis technology to ensure simple operation and intelligent functioning of the equipment. It supports switching between XPH and standard MODBUS dual protocols; it can support JSON/HTTP data reporting.

·Can utilize LoRa or NB-lot technologies to expand access to field environmental collection devices and field irrigation control equipment.

Appearance characteristics

·Built-in system stainless steel centrifugal pump, filtration system, monitoring and control system, electrical cabinet, fertilizer tank, and suction channel assembly.

·10 inch touch screen display

·Wireless transmission in the greenhouse reduces cabling costs.

·The system comes standard with 3 fertilizer injection channels (1 additional channel reserved), with a single-channel fertilization capacity of 420 L/h.

·Can integrate with IoT platforms for intelligent fertilization proportioning based on collected soil moisture and other data, automatically recording fertilization time, area, flow rate, pH level, EC value, usage amount, etc.

Safety Air Vent Valve

Exhaust and intake functions: expels air from pipelines or equipment when the pump starts to ensure safe operation and prevent strong airflow impact; prevents negative pressure when the system stops by drawing in a large volume of gas to maintain consistent pressure between the system and atmospheric pressure, avoiding damage from negative pressure suction.

Wireless Valve Controller is a new product developed based on 470MHz wireless transmission technology. It is primarily used in irrigation systems, allowing customized irrigation strategies to be set via a control terminal according to crop-specific watering requirements, achieving personalized irrigation.

Power supply method: 18650 battery;

Solar panel: 3W;

Working frequency band: 470MHz;

Modulation method: LORA

Communication distance:> 2KM

Number of pulse valves: Standard configuration: 1 channel, expandable to 2 pulse valves; Pulse valve power supply: 9-40V pulse signal (supports mainstream valves such as Bermad, Netafim, Rain Bird, etc.).

Integrates multiple sensors (valve outlet pressure, soil moisture, flow, etc.); supports timed automatic on/off and allows configuration of interlinked logic with sensors.

IoT platform system

Integrated water and fertilizer irrigation systems enable producers to conveniently achieve automated water and fertilizer management. The system comprises a central control software system, regional control cabinets, branch controllers, transmitters, and data acquisition terminals. Through seamless integration with water supply systems, it realizes intelligent control, including automated monitoring and regulation of irrigation duration, fertilizer concentration, and water supply volume. Transmitters (soil moisture transmitters, flow transmitters, etc.) continuously monitor irrigation conditions. When soil moisture in the irrigation zone reaches a preset lower threshold, solenoid valves automatically open. The valves automatically close when soil moisture content and liquid levels meet predetermined irrigation quotas. The system schedules rotational operation of solenoid valves across the irrigation zone based on time periods, while also supporting manual irrigation control and soil moisture data collection. The coordinated system implements rotational irrigation to maximize water efficiency, conserve water and energy, reduce labor intensity, and minimize operational costs. Through PCs and smartphones, users gain real-time monitoring of field meteorological conditions, soil status, and water source control. Integrated with greenhouse irrigation management, live video streaming, and intelligent alerts, the system empowers agricultural operators to monitor crop growth trends and environmental changes anytime, anywhere, delivering an efficient and powerful agricultural monitoring solution. The system includes a monitoring center, reporting center, and task center. Additionally, users can customize irrigation parameters such as timing, duration, frequency, and valve opening levels.

Computer, smartphone, and cloud interfaces

The user information query and operational interface should be compatible with most browsers, ensuring device-agnostic access. It must be simple, installation-free, and user-friendly. The agricultural IoT system platform can serve as a comprehensive farm information system and control management platform for management and control. Configurable with various functional modules, it flexibly enables site-specific environmental data collection, control, and management.

苏公网安备 32050902101529号

苏公网安备 32050902101529号 Scan WeChat QR to Follow

Scan WeChat QR to Follow