I. Stringent Water Quality Requirements in Chip Manufacturing

As the "crown jewel" of modern industry, chip production involves complex and time-consuming processes. From wafer arrival to final packaging and testing, the production cycle typically requires at least three months, with the total supply chain timeline often exceeding six months when accounting for other factors. Every step in chip manufacturing demands rigorous control, particularly over water quality. Ordinary tap water contains high levels of ions, microorganisms, and bacteria, which, if introduced into the manufacturing process, would directly increase product defect rates and compromise batch quality. Therefore, chip manufacturing relies on Ultra-Pure Water (UPW)—a type of water with near-zero levels of ions, organics, particles, and microorganisms. The preparation of UPW involves highly sophisticated technologies and stringent requirements. In chip manufacturing, UPW is widely used in critical processes such as photolithography, etching, cleaning, and packaging. It ensures contamination-free chip surfaces, improving product yield and consistency, thereby providing robust support for high-end manufacturing.

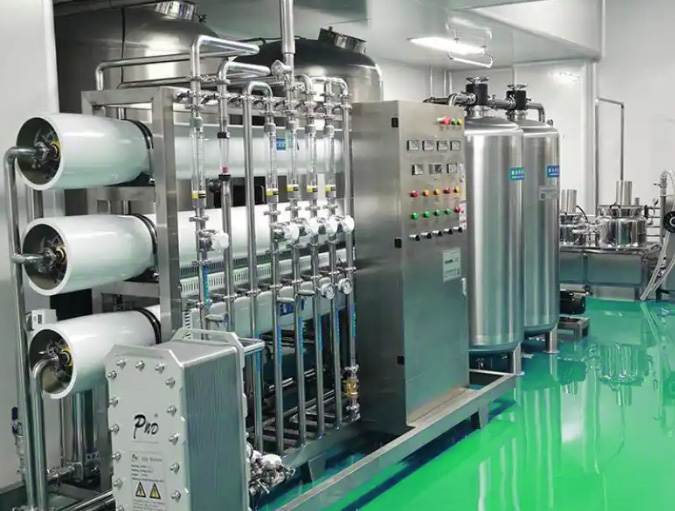

II.Core Technologies ofUltra pure water equipment.

To meet the stringent water quality demands of chip manufacturing, mainstream ultra-pure water systems employ reverse osmosis (RO), electrodeionization(EDI), and mixed-bed modular designs to produce UPW that fully complies with industry standards. This process offers the following advantages:

- Environmental Sustainability: Advanced membrane separation technologies significantly reduce wastewater discharge, enabling green production.

- Economic Efficiency: Optimized system design lowers energy consumption and operational costs.

- High Reliability: Proprietary chemical cleaning technologies for membrane components prevent microbial contamination, enhancing system stability and lifespan.

- Growth Potential: As chip manufacturing advances toward smaller process nodes, continuous innovation in UPW equipment ensures compatibility with future high-precision requirements.

Compared to similar systems, this equipment delivers superior cost-effectiveness and reliability, effectively safeguarding chip quality.

III. Broad Applications of Ultra-Pure Water Equipment

Ultra-pure water systems play an irreplaceable role not only in chip manufacturing but also across multiple industries:

- Electronics: Used in semiconductor device fabrication, LCD production, and PCB cleaning.

- Power Industry: Applied in boiler feedwater treatment for thermal power plants to ensure long-term operational stability.

- Paper Industry: Utilized in high-quality pulp production to avoid contamination.

- Consumer Goods: Ensures safety and purity in cosmetics, pharmaceuticals, and food production.

Amid growing global emphasis on sustainability, innovations in UPW equipment continue to advance. By optimizing membrane structures and improving system recovery rates, these systems reduce wastewater discharge while maintaining water quality, achieving economic and environmental synergy.

IV. Future Outlook

At Sulco Environmental, we believe that the powerful combination of ultra-pure water systems and membrane separation technologies will not only help the chip industry overcome developmental bottlenecks but also lay a solid foundation for China’s high-end manufacturing sector to globalize. The future is here—let us witness the boundless possibilities together!

苏公网安备 32050902101529号

苏公网安备 32050902101529号 Scan WeChat QR to Follow

Scan WeChat QR to Follow