With China's Increasing Environmental Protection Requirements, urban wastewater treatment plants are facing stricter discharge standards. To meet higher water quality requirements and achieve wastewater resource utilization goals, advanced treatment technologies and efficient equipment systems must be adopted. This article introduces key technologies and equipment involved in the upgrading of urban wastewater treatment plants and explores their practical applications.

I. Ultra-Fine Screen System

To address the new process requirements for high discharge standards in urban wastewater treatment plants, a novel inflow ultra-fine screen system has been developed through the localization and improvement of international advanced technologies. This system achieves 0.75–1.5mm variable-pore ultra-fine screening with a maximum single-unit treatment capacity of 25,000 to 100,000 tons/day. By combining medium- and high-pressure cleaning modes, it significantly enhances anti-clogging performance. This innovation ensures more efficient and reliable pretreatment while achieving full domestic production. Its performance and lifespan match international counterparts, yet costs are far lower than imported systems.

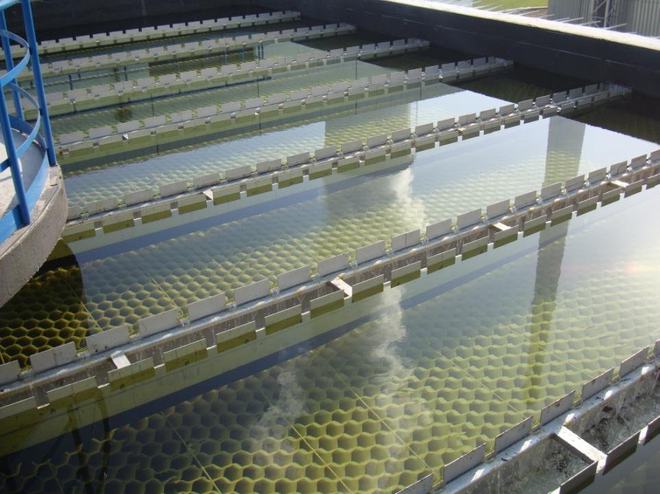

II. High-Efficiency Sedimentation Tank SystemTraditional sedimentation tanks suffer from low static settling efficiency. By integrating domestic and international technologies, a high-efficiency sedimentation tank solution has been introduced. It optimizes primary sedimentation sludge levels and hydraulic flow patterns to form a high-concentration suspended sludge layer, improving organic particle removal. This enhancement stabilizes influent carbon source structures, mitigates fluctuations in water quality/quantity, and reduces energy consumption. The system now offers standardized products ranging from 2,000 to 50,000 m³/day.

III. Suspended Carrier Biofilm Reactor SystemSuspended carriers are critical for biological treatment. To resolve slow carrier deployment, a suspended carrier system (including carriers, aeration/mixing systems, interception screens, and control systems) has been developed for plug-flow channels and SBR reactors. A rapid carrier deployment device prototype has also been designed, shortening construction cycles and enhancing biofilm performance. These innovations enable batch production and broader application of suspended carrier systems.

IV.MBRMembrane Modules and MBR SystemsMembrane Bioreactor (MBR) technology, combining membrane separation with activated sludge processes, is a key advancement in wastewater treatment. By optimizing membrane fiber packing density, aeration methods, and integrating high-quality components, a modular pulsed aeration device has been developed, reducing energy consumption by ≥40%. A production base for 30 million m²/year of hollow-fiber ultrafiltration membranes has been established, promoting standardized MBR module production and flexible treatment solutions.

V. Submersible Mixer SystemSubmersible mixers critically influence hydrodynamic characteristics and treatment efficiency. Through optimized impeller designs and mold processing, coupled with studies on suspended carrier integration, system stability and adaptability have been significantly improved.

VI. Wall-Mounted Recirculation Pump SystemTo address high energy consumption and reliability issues in internal recirculation pumps, new electromechanical technologies and variable-frequency control strategies have been introduced. These solutions enhance pump efficiency and ensure long-term stable operation of sludge recirculation in biological units.

VII. Biological Filter SystemTo meet Class IV surface water standards, studies on denitrifying filter performance (carbon and nitrogen removal under low carbon conditions) have been conducted. Optimal configurations for carbon-to-nitrogen ratios and backwash cycles have been identified. Standardized equipment design is underway to support upgrading projects.

VIII. Active Sand Filter SystemActive sand filters play a vital role in advanced SS and TP removal. Technical improvements, such as sand lifting/washing system optimization and online control under dynamic conditions, ensure stable effluent quality and reduce chemical usage.

IX. UV Disinfection SystemUV disinfection is widely used for its high-efficiency sterilization. The newly developed large-scale UV disinfection system has been deployed in multiple major projects, treating over 940,000 tons/day of wastewater, demonstrating strong market competitiveness.

X. Ozone Disinfection SystemThe integrated large-scale ozone generator achieves ozone concentrations >12%wt with energy consumption <10 kWh/kg. It has been widely adopted in urban wastewater plant upgrades nationwide.

Sulco Environmental focuses on system design and installation, leveraging years of technological integration experience to innovate and refine wastewater treatment solutions. As environmental regulations tighten and technology advances, more breakthroughs will emerge, advancing water environment governance in China and globally.

苏公网安备 32050902101529号

苏公网安备 32050902101529号 Scan WeChat QR to Follow

Scan WeChat QR to Follow